The last couple of pandemic years have been unpredictable for businesses worldwide. Though the crisis has created daunting challenges, there is no questioning that it has also unlocked digital potential. Businesses across all industries have been forced to adopt remote working, fundamentally changing the workplace. And the mining and metal industry is no exception.

Though digital transformation was already underway in the mining sector before 2020, the pandemic has impacted its pace and nature. It has reinforced the industry’s need for full digital transformation and accelerated the timeline for existing transformation efforts. A digital transformation company can help mining companies accelerate this journey by providing the tools, expertise, and strategies needed to make this shift smoothly.

With the future of intelligent mining on the horizon, now is the time for change. It’s not about adopting the latest digital technologies and capabilities. It’s about imbibing digital thinking into the heart of business strategies and practices to transform the mining industry’s operations.

Useful link: Digital Transformation: Avoid 8 Most Common Pitfalls

How Digital Transformation Benefits Mining and Metals?

Digital transformation shows great promise for the mining and metals industry, which desperately needs a makeover. It can create a more agile and profitable business with improved decision-making and employee empowerment. Moreover, digitalization can reduce geological uncertainty, market volatility, and operational risks and improve health, safety, and environmental impact.

According to a recent World Economic Forum report, by 2025, digitalization in the mining and metals industry could create:

- USD 425 billion – potential value addition for the industry, customers, society, and environment

- USD 320 billion – potential value for the industry

- USD 190 billion – potential value for the mining sector

- USD 130 billion – potential value for the metals sector

- 610 million tonnes – reduction in CO2 emission

- 1,000 lives – estimated number of lives saved

- 44,000 injuries – estimated number of injuries avoided

The Bumpy Road to the Future of Digital Mining

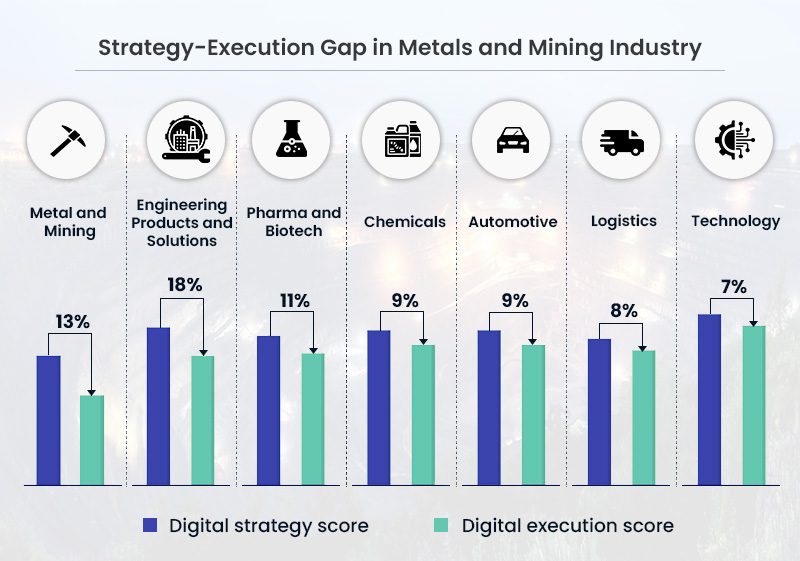

Many metals and mining companies have already started investing in digital technologies. However, many of these investments are insignificant compared to their potential, courtesy of the industry’s unique barriers. According to BCG’s Digital Acceleration Index (DAI), the metals and mining industry is around 30-40% less digitally mature than other industries like automotive and technology.

Moreover, the mining industry has a significant gap between its digital transformation strategy and execution. The prime reasons for this gap are the lack of customized solutions, the use of traditional waterfall methodologies to deploy digital technologies, and the neglect of solutions’ sustainability.

So, how can the metal and mining industry navigate the digital barriers to unearth the true potential of digital transformation? Read on…

How Can the Mining Industry Achieve Successful Digital Transformation?

Mining companies must embed digital thinking, processes, and structures into their entire organizations to unlock the full value of digitalization. While many miners strive to achieve true digital transformation, they lack visibility and struggle to execute an effective digital strategy.

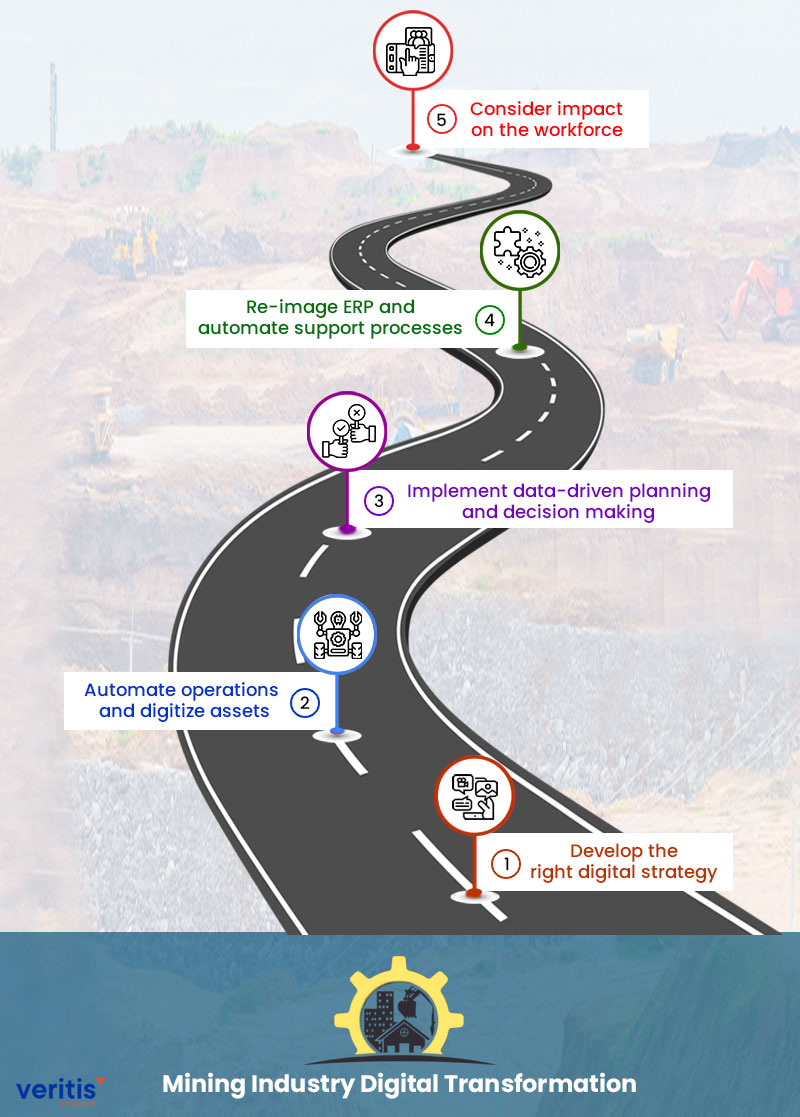

Here are some considerations for mining companies to thrive in the digital future:

1) Develop the right digital strategy

The mining companies must develop an enterprise-level digital strategy that clearly defines the value the digital initiatives create to the organization. The strategy must deliver digital business transformation at a speed that attains short-term goals while ensuring flexibility to enable longer-term transformation. Moreover, it must consider all the products and platforms that make a complete solution for the future digital mine.

2) Automate operations and digitize assets

Organizations must deploy various digital capabilities to automate core operations in the mining value chain. For instance, IoT and Machine Learning must be used to automate and improve the reliability of mining equipment and trucks, sensors to capture data in real-time, drones for data collection, inspection, and stock control, and wearables for field maintenance and operator safety.

3) Implement data-driven planning and decision-making

Though the direct benefits of automation and digitization are significant, more excellent value will be realized only when data is used to plan, optimize, and integrate activities across the value chain. Mining companies must develop and deploy data science and analytic skills and foundational data platforms and analytic tools to bring together data across the value chain over multiple time horizons.

This helps improve planning, control, and decision-making to optimize complex systems and operations from pit to customer.

4) Re-image ERP and automate support processes

The ripple effect of digital transformation will go beyond the core mining operations to the supporting processes and systems such as supply, HR, and finance. So, companies must reimagine enterprise resource planning (ERP) and other processes using digital solutions that enable low ownership costs and the latest user interfaces.

Robotic Process Automation (RPA) must be utilized to automate repetitive manual activities and reduce costs and errors in back-office support processes and shared services.

5) Consider the impact on the workforce

Digital transformation in the labor-intensive mining industry will significantly impact the workforce in many ways. With increased human-machine interaction, the digital mine can employ a diverse workforce, including on-shore, off-shore, distributed, remote, mobile, and connected employees.

Real-World Application: Manufacturing Transformation Through Digital Technologies

To understand how the critical components of digital transformation come together, consider how Veritis helped a leading manufacturing client modernize its operations:

Challenge: The client faced issues with outdated systems, unexpected equipment failures, and inconsistent product quality, resulting in high operational costs.

Solution: Veritis implemented a comprehensive digital strategy, integrating IoT sensors for real-time monitoring, predictive analytics for proactive maintenance, and automation tools for quality control.

Impact:

- 30% reduction in downtime

- 20% reduction in maintenance costs

- 15% improvement in product quality and customer satisfaction

This case illustrates how IoT, analytics, and automation, key components of digital transformation, can drive measurable improvements in manufacturing efficiency.

Read the Full Case Study: Leveraging Digital Technologies for Manufacturing Success

In Conclusion

The path to digital mining is less about capitalizing on new technology and more about business leaders embracing a new way of operating, data-driven decision-making, and diverse skills and capabilities. This will be daunting for mining companies, which often face digital talent scarcity. To make the digital transition successfully, they must recruit new skills while supporting their experienced workforce.

With the digital landscape evolving rapidly, now is the best time to explore Intelligent Mining!

Veritis Can Help!

Work with Veritis to kick-start your digital mine transformation today. We help you implement a sustainable digital transformation, providing the required multidisciplinary digital skills and deep industry expertise through our comprehensive digital transformation services.

Key Takeaways:

- The pandemic has accelerated the mining industry’s digital transformation efforts.

- With the future of intelligent mining on the horizon, now is the time for change.

- Imbibing digital thinking into the heart of business strategies and practices is essential to achieving digital success.

By partnering with digital transformation service providers like Veritis, you can leverage the latest technologies and strategies to drive innovation, improve efficiency, and stay ahead in the competitive mining industry. Let us help you embrace the future of intelligent mining through proven digital solutions.

Let’s talk!

More Digital Transformation Articles:

- Factors That Can Drive Your ‘Digital Transformation’ Initiatives

- White Paper: Importance and Benefits of Digital Transformation

- Infographic: 16 Facts ‘Upward Trend’ For Digital Transformation

- Digital Transformation Market to Reach USD 1009.8 Billion by 2025

- Top 10 Digital Transformation Trends for 2025 and Further

- Digital Transformation Vs. Business Transformation